Introduction

Barcode scanners are pivotal in speeding up processes, reducing manual errors, and boosting overall efficiency across retail, logistics, healthcare, and manufacturing. However, with various models and technologies available, selecting the appropriate barcode scanner for your business requires carefully evaluating key features. From performance quality to integrations, understanding your options can lead to better productivity and a solid return on investment. Whether you’re weighing the benefits of an Android-based barcode scanner or are unsure which connectivity option to select, a thoughtful approach ensures you choose hardware that fits your workflow.

The decision goes far beyond picking the most popular model. Today’s scanners are designed for specialized uses – ranging from compact styles for retail counters to rugged devices built for industrial floors. Features like scanning speed, durability in harsh environments, and compatibility with different barcode types are crucial in everyday efficiency. Other considerations, such as user comfort, battery life, and integration with your inventory or point-of-sale software, factor into your long-term satisfaction and cost management.

Scanning Performance

The foundation of any effective barcode scanner is its scanning performance. Businesses often operate in fast-paced environments where quick and precise barcode reading determines productivity. Opt for scanners with high-speed image sensors and advanced decoding algorithms capable of reading barcodes even if they are damaged, poorly printed, or smudged. Scrolling from a distance or capturing barcodes on screens enhances flexibility, especially in omnichannel retail or logistics. According to IntelliStride, efficient barcode systems streamline operations and can lead to significant time savings.

Durability & Build Quality

Durability takes center stage in warehouses, distribution centers, and manufacturing plants. Scanners designed with reinforced casings, rubberized housings, and high Ingress Protection (IP) ratings offer reliable performance against drops, dust, and water exposure. While retail scanners might focus more on sleek aesthetics, industries with rough environments must prioritize models with drop-test certifications and eco-sealed designs—ensuring that device longevity and dependability are not compromised.

Connectivity Options

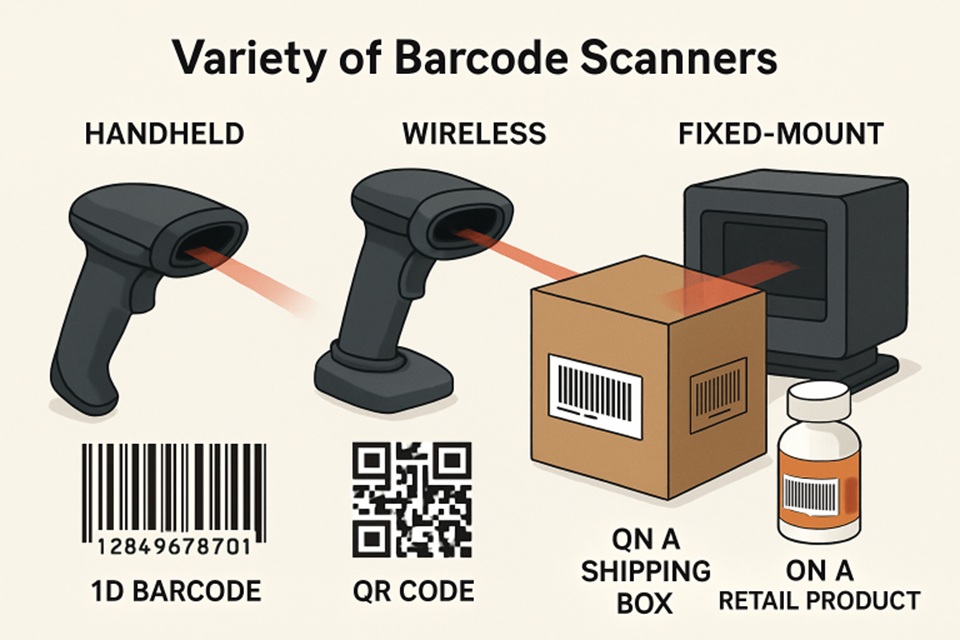

Your operational flow largely determines whether you need a wired or wireless barcode scanner. Wireless scanners facilitate mobility through Bluetooth or Wi-Fi connections, making them ideal for large warehouses and enterprises with frequent movement. However, they require careful battery management. Wired options provide continuous, stable connectivity, suiting stationary point-of-sale stations or desk-based data entry. Some advanced scanners even offer hybrid modes, allowing a transition between wireless and wired as needed to fit evolving workflows.

Ergonomics & User Comfort

Staff can often use scanners for several hours at a stretch, and ergonomics dramatically affect overall job satisfaction and productivity. Lightweight build, balanced grip, intuitive trigger positioning, and easy-to-press buttons reduce user fatigue and prevent repetitive strain injuries. Look for ergonomic certifications or user-tested designs, particularly if you operate in high-volume or long-shift environments.

Battery Life & Power Management

Wireless barcode scanners rely on rechargeable batteries, so long battery life is essential for avoiding frequent disruptions. For maximum reliability, select devices that can operate through a full shift—or up to 24 hours—for maximum reliability. Power-saving features such as auto sleep, rapid standby, and efficient recharging help extend battery lifespan while reducing downtime. Some models also offer hot-swappable batteries, providing flexibility during peak operational hours.

Compatibility With Barcode Types

Barcode technology is constantly evolving. While many businesses still use traditional 1D barcodes, 2D codes like QR codes are gaining traction for inventory tracking, marketing, and authentication. Choose a scanner capable of reading multiple barcode symbologies for maximum versatility. This ensures your scanner remains useful as your business needs and industry standards change. You can find more about how barcode technology is changing inventory management in this resource from Manufacturer Electronic.

Integration With Existing Systems

A barcode scanner should integrate seamlessly with your current point-of-sale (POS), warehouse management (WMS), or enterprise resource planning (ERP) systems, eliminating the headache of manual workarounds. Look for pre-configured models for common software platforms, and ensure compatibility with your operating systems—whether Windows, Android, or iOS. Some scanners come with software development kits (SDKs) or APIs, making configuring custom workflows easier or scaling your solution as your business grows.

Cost & Total Cost Of Ownership

While the upfront price of a scanner might be an obvious factor, the total cost of ownership deserves equal attention. Maintenance, expected lifespan, manufacturer support, and the cost of accessory replacements (such as batteries or cables) add up over the years. Investing in a rugged, high-quality scanner may cost more initially, but it often leads to greater savings by reducing downtime, repairs, and costly human errors in the long run.

Conclusion

Evaluating barcode scanners with a comprehensive list of essential features enables you to select the correct device for your organization’s unique requirements. By focusing on performance, durability, connectivity, ergonomics, compatibility, system integration, and overall cost, you position your business for maximum return on investment and enduring operational success.