Key Takeaways:

- Flexible metal tubing is a critical engineered component used across construction, energy, medical, and industrial applications.

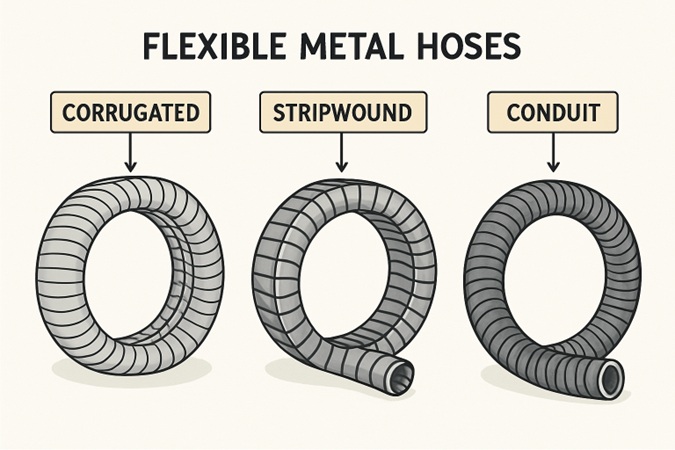

- Different tubing types serve distinct purposes, including corrugated hoses for pressure and movement, stripwound hoses for mechanical protection, and conduits for electrical routing.

- Proper selection improves system safety, longevity, and compliance with industry regulations.

- Corrugated stainless steel tubing (CSST) offers efficient installation for gas distribution but requires proper bonding and grounding.

- Liquid-tight and standard flexible metal conduits provide adaptable solutions for dry, wet, and hazardous environments.

- Understanding application requirements and industry standards helps prevent failures, downtime, and safety risks.

Introduction

Flexible metal tubing plays a vital role across numerous industries. Its unique properties help address durability, installation in tight spaces, and resistance to chemicals, heat, and vibration. By selecting the appropriate type of flexible metal tubing, organizations can ensure optimal performance while complying with strict safety regulations. Interlocked flexible metal tubing Addison, IL is commonly used in applications where strength, flexibility, and reliability are critical.

This guide covers the primary types of flexible metal tubing, their features, and where each is best suited. Whether you are an engineer, facility manager, or procurement specialist, understanding these distinctions can help prevent costly mistakes or downtime.

Flexible metal tubing is not just a commodity product. It is a carefully engineered component. Its correct application enhances system longevity, safety, and adaptability in sectors as diverse as energy, medical devices, and construction.

Many industries depend on proper metal hose selection for mission-critical operations. From preventing gas leaks in buildings to delivering medical precision, flexible tubing is an indispensable technology.

Corrugated Flexible Metal Hose

Corrugated flexible metal hoses are manufactured by shaping thin metal walls into annular or helical corrugations, which gives them bendability without sacrificing pressure containment. This makes them especially useful for transferring fluids or gases that fluctuate in temperature or pressure. Their flexibility allows them to adapt to movement, absorb mechanical vibration, and compensate for thermal expansion.

Industries such as aerospace, chemical processing, and mechanical engineering often rely on corrugated hoses to handle challenging media or to absorb equipment movement. These hoses are available in various alloys to suit different chemical or thermal requirements.

Stripwound Metal Hose

Stripwound metal hoses are constructed by helically winding thin metal strips that interlock to provide mechanical strength and structural flexibility. However, these hoses are not typically gas- or liquid-tight, making them better suited as protective coverings for sensitive cables, wiring, or other hose assemblies.

The mechanical durability of stripwound hoses ensures reliable protection for industrial control wires or fiber optic cables in harsh conditions. Industries such as telecommunications, automotive production, and robotics often utilize stripwound designs when abrasion, puncture, or crushing protection is a priority.

Corrugated Stainless Steel Tubing (CSST)

Corrugated stainless steel tubing (CSST) represents a significant advancement in building utilities. These tubes are highly flexible stainless steel products that typically feature a plastic outer jacket for added protection. CSST is widely adopted for fuel gas distribution in both commercial and residential buildings, as its flexibility allows easier routing through walls and over obstacles, reducing installation labor and materials costs compared to rigid piping.

The primary advantage of CSST is its quick, versatile installation, but correct bonding and grounding are essential for safety. Always consult local codes and have CSST installed by a trained professional, as improper use may pose serious hazards.

Flexible Metal Conduit (FMC)

Flexible metal conduit, commonly called FMC or “Greenfield,” is made from interlocked galvanized steel or aluminum without additional coatings. This form of tubing allows wiring to be routed efficiently around building obstacles or tight corners, particularly in environments where vibration or frequent modifications are expected.

FMC is best used in indoor dry locations. While it offers impressive protection and flexibility, FMC is not rated for wet or damp environments. Always check if your application needs Extra Flex conduit or if standard FMC is sufficient for the expected mechanical stresses and configurations.

Liquid-Tight Flexible Metal Conduit (LFMC)

Liquid-tight flexible metal conduit (LFMC) features a thermoplastic waterproof jacket over the metal core, allowing it to be used in environments where exposure to water, oil, or other liquids is likely. Its construction is otherwise similar to standard FMC, but the robust outer layer resists chemicals, UV radiation, and abrasion.

LFMC is frequently used outdoors, in car washes, wastewater treatment plants, and industrial facilities with spray or spill hazards. Its flexibility ensures that complex wiring systems can be safely protected in dynamic settings with minimal installation challenges.

Applications Across Industries

Flexible metal tubing has a wide variety of uses across leading industries. In medical device manufacturing, flexible tubing helps designers create minimally invasive instruments and endovascular tools that demand precision and maneuverability. Customizable diameters and wall thicknesses ensure compatibility with delicate clinical procedures.

In construction, flexible metal tubing simplifies the installation of gas lines, HVAC ductwork, and fire sprinkler systems. Its adaptability speeds construction projects and enables retrofitting older buildings without costly structural changes. The energy and utility sectors depend on metal tubing in power plants, refineries, and LNG facilities to handle both routine service and extreme operating conditions, like elevated pressures or temperatures.

Final Thoughts

Selecting the correct type of flexible metal tubing is essential for maintaining performance, safety, and compliance in advanced systems. By understanding what sets each design apart, whether it is corrugated metal hose for high-pressure flexibility, stripwound hose for rugged cable protection, or liquid-tight conduit for wet installations, you can make informed decisions tailored to your project needs.

Stay informed on industry best practices and consult recognized standards when choosing tubing for mission-critical installations. With the correct approach, flexible metal tubing delivers lasting value and safety in the world’s most demanding environments.